In the highly competitive market for finished leathers, quality, durability and sustainability are decisive factors for companies seeking to create high standard products, and Durli High Quality Finished Leather stands out in this scenario, where quality is a determining factor for the success of these products in the market.

Durli Leathers, with over 64 years' experience in the sector, takes these concepts to the next level by offering finished leathers that combine cutting-edge technology, sustainable processes and an unwavering commitment to excellence.

Find out how Durli High Quality Finished Leather meets the highest demands of different markets, such as footwear, furniture and automotive, and discover why it has become a benchmark in strategic partnership, agility and consistent quality.

The Durli Finished Leather Production Process

Durli Leathers stands out for its expertise in transforming fresh hides into wet blue, from this to semi-finished hides and in the finishing process, the final stage in the industrialization of leather.

Selection, Leather Preparation and Tanning

The process begins with the selection of high-quality hides from suppliers who guarantee the responsible and traceable origin of each piece. The hides are cleaned and prepared for tanning. At this stage, the hides are treated with tanning agents that stabilize the collagen fibres, giving the leather strength and durability. Durli Leathers uses techniques that guarantee the consistency and quality of the wet blue leather, the basis for the subsequent stages.

Retanning and Drying

Wet blue leather goes through a retanning process, where dyes and agents are added to define the desired softness and texture. After retanning, the leather is dried and softened, preparing it for the final finish.

Finishing

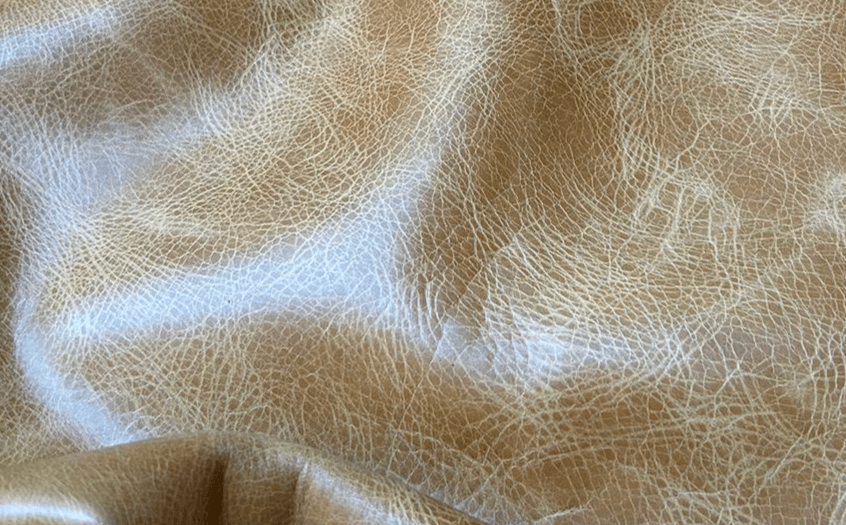

Finishing is the stage that gives leather its final aesthetic and functional characteristics. It involves processes such as painting, engraving, polishing and softening, which enhance the appearance and durability of the material. This fundamental stage transforms semi-finished leather into its most refined form, finished leather ready for use in top quality products such as footwear, bags, automotive upholstery and furniture.

In recent years, the Durli Leathers production unit in Erechim-RS has received significant investments in technology. State-of-the-art machines have been acquired that optimize every stage of finishing. This has resulted in products with superior quality and a reduced environmental impact.

Among the new equipment are texturing and stamping presses and advanced painting machines. This guarantees better use of paint, lower water consumption and reduced gas emissions. In addition to compact drying tunnels that increase productivity with lower energy consumption.

The Importance of Technology in Finished Leather

The application of the latest technology allows Durli Leathers to offer finished leather that goes beyond expectations. The painting machines, for example, not only provide a uniform finish, but also maximize resource efficiency.

With this innovation, Durli High Quality Finished Leather combines impeccable aesthetics with durability, while remaining in line with the strict environmental and quality standards demanded by global markets.

In addition, the finishing process does not use chemical solvents, and all the effluents generated are fully treated in our own effluent treatment plant (ETE), operating sustainably and without impact on the environment. We use products from the world's best suppliers in the chemical industry, ensuring that our formulations meet the most demanding markets in the world.

Customization and Flexibility: The Finished Leather that Meets All Markets

One of the great advantages of Durli Leathers is the ability to offer customized volumes to meet the specific needs of each client and segment.

Whether for automotive upholstery, furniture, bags or shoes, the finished leather is tailored to the customer's specifications.

Suitability for End Use

Each leather application requires a specific type of finish. In the case of footwear, for example, it is essential that the leather is resistant to constant wear. While leather used for furniture needs to have a refined aesthetic and be pleasant to the touch.

Durli Leathers ensures that each piece of high-quality finished leather has the flexibility and strength required for its final use, while maintaining integrity and durability. Characteristics that are highly valued.

In fact, we have a whole blog on our ideal leathers for shoe manufacturers.

Sustainability and Certifications: Guarantee of Quality and Origin

Trust and confidence in the origin of products are essential for today's buyers. Durli Leathers reinforces this confidence with globally recognized certifications such as LWG Gold (Leather Working Group) and ISO 9001.

These certifications audit compliance and performance in sustainability, traceability and quality.

Benefits of Durli High Quality Finished Leather

For decades, Durli Leathers has been at the forefront of technology and innovation in the leather sector, always prioritizing quality and sustainability.

The finished leather on offer stands out for its exceptional characteristics:

Protection and sophistication

Finished leather is not only visually appealing, but also highly resistant.

We apply specific coatings to protect the leather against water, dirt and wear.

This ensures that the final products retain their beauty and functionality for many years to come.

Diversity of Patterns and Textures

Leather finishing involves precise mechanical operations, such as hydraulic presses and engraving systems, which guarantee unique patterns and textures.

This makes it possible to create customized products, meeting the most diverse style and design demands of each client.

Flexibility and durability

We develop each piece of finished leather to offer optimum flexibility and resistance for its final application.

Whether it's a pair of high-quality shoes, a sophisticated handbag or automotive upholstery, Durli leather guarantees durability and flexibility.

High Quality Finished Leather Applications

The high-quality finished leather produced by Durli Leathers is widely used in various sectors:

-

- Footwear industry: Leather offers flexibility, resistance and superior aesthetics, which are essential for the production of high-end footwear.

-

- Furniture: In the furniture sector, finished leather adds elegance and durability to sofas, armchairs and other upholstered furniture.

-

- Automotive: Leather is used in the interior coverings of seats, dashboards, steering wheels, handles and vehicle accessories, providing comfort and a premium finish.

-

- Artifacts: Handbags, belts and other fashion accessories benefit from the quality and beauty of finished leather.

Durli Leathers: A Strategic Partner for the Future

In short, Durli Leathers is more than a leather supplier, it is a strategic partner for companies in the automotive, furniture and footwear sectors.

With a highly specialized commercial and technical team, we offer continuous support to customers, helping them to overcome challenges and respond quickly to market changes.

So, if you're looking for high quality finished leathers, resistance, durability and a sustainable approach, Durli Leathers is the ideal partner for your business.