High quality Durli leathers

Attention to detail

For us, right from the raw material, leather is a unique product. And handling it, as well as a craft for which we have the know-how and technology, is an art. These are activities and processes that we master from start to finish.

We are specialists in the production and stable supply of wet blue, semi-finished and finished leathers.

Our products are distinguished by their excellence and are classified according to high quality standards, from their monitored origin to their tracked delivery, to enrich the most varied parts of the automotive, furniture, footwear and artifacts sectors with all their beauty, durability and nobility.

Durli Leathers differentials:

Wet Blue, Semi-finished and Finished

A success story in the production of high quality wet blue leather in Brazil.

Raw materials from suppliers that guarantee high quality with responsible traceable origination of each piece.

The details are meticulously aligned with customer demands, producing according to the particularities of each item and specifications.

Color, softness and texture treatment carried out using innovative and careful techniques by highly trained professionals.

Production with standardized formulations, inputs and products of excellence and high technology.

Strict quality control of products, processes and technical criteria, which guarantees uniform production.

Agile delivery through advanced logistics, with our own transport fleet and strategic plant locations.

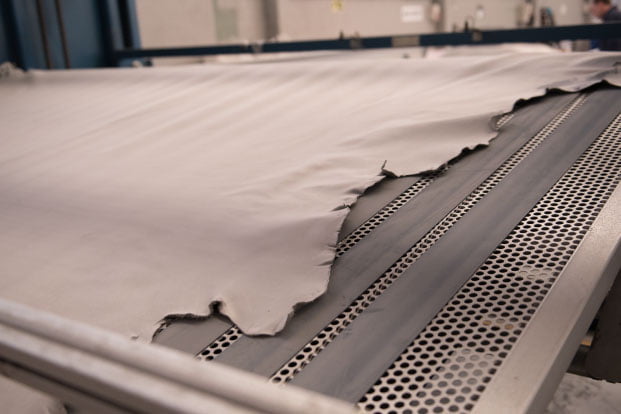

Wet Blue leather

It is in this tanning process that the hides, which have a moist, bluish appearance, become preserved and resistant. And it's always good to remember that Durli Leathers has a successful history of producing Wet Blue leather in Brazil.

Partnerships built up over the years allow us to follow the sorting process closely and have access to high-quality hides. Through our volume and strict control of our raw materials, we always maintain a high standard in the quality of the hides, the quantities contracted and the punctuality of deliveries.

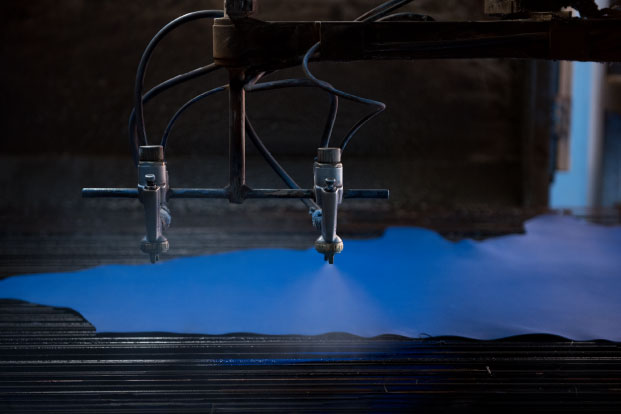

Semi-finished leather - Crust

Crust or semi-finished leather is the result of the transformation of Wet Blue leather after retanning.

At this stage, the leather already has more defined characteristics. The treatment of color, softness and texture is carried out using modern techniques by highly trained professionals.

At Durli Leathers, we are committed to the final order and customer satisfaction. For our leather to exceed expectations, every detail is meticulously aligned.

Finished leather

This product represents the last stage of leather industrialization. It is here that we deliver the material completely finished according to the particularities of each article in which it will be applied, according to the client's specifications.

Through our logistics structure, with our own transport fleet, we strengthen our commitment to the agility and precision of our batches. So the leather goes to the industry through strict quality controls, metering and compliance with contracted deadlines and quantities. There it will apply all its beauty, durability and nobility to the most varied shapes and objects valued by Durli leather.

Capacity Hides/Year

Durli leathers produced in wet blue, semi-finished and finished in the 9 industrial units Durli Leathers with LWG Gold certification.

The process of creating Durli leather

Tanning stages

Leather tanning is an artisanal tradition that has been passed down from generation to generation and which today still combines a great deal of science and technology for exceptional results.

Durli Leathers respects and retains the best of ancient knowledge, while constantly investing in technology and equipment. In this way, we have a tradition in the art of converting raw leather into a noble, resistant and desirable material.

Tradition, knowledge and technology are driving us towards our vision of being a benchmark among the world's leading leather producers.

We've been specializing in leather since 1960

Leather tanning is a tradition that has been improved by science, technology and a lot of work by Durli Leathers.

The Beginning

At this stage, the hides are prepared for tanning. Trimming and stripping, as well as other manual and mechanical operations, are part of this first process in the transformation of Durli Leathers leather.

Tanning

Wet Blue

This is a decisive stage for the quality of all subsequent processes for Durli leathers or our customers' processes. At this stage, the tanned leather gains strength and stability. It is then graded according to standards that attest to its quality scale.

In its wet blue state, leather retains its natural characteristics unchanged and is ready to be the high-quality, resistant and durable base for the next stages, semi-finished and finished.

At this stage it can already be stored for further stages or sold to the privileged customers of Durli Leathers.

Semi-finished

In the Semi-finished stage, the meticulous sequence of retanning processes takes place.

It's time to carefully define the thickness, color and softness of the leather under the expert eye of our technical team. The goal is always 100% compliance for our leathers.

Finished

Durli Leathers - Manufacturing Industry

Durli Leathers is an industry that combines the art and tradition of its founders with science and technology. Today, this combination excels in converting raw leather into a noble, resistant material that is valued and desired by many.

A true work of re-creation, which takes a product that would otherwise be waste from meat and dairy production and elevates it to the nobility of leather. Durli Leathers does it masterfully and is passionate about what it does!